An Intensive 5-day Training Course

Principles, Applications and Performance of Pumps, Compressors and Turbines

- Format: Classroom

- Duration: 5 days

- Language: English

- Accredited: CPE, KHDA Certified training courses

CLASSROOM DATES

INTRODUCTION

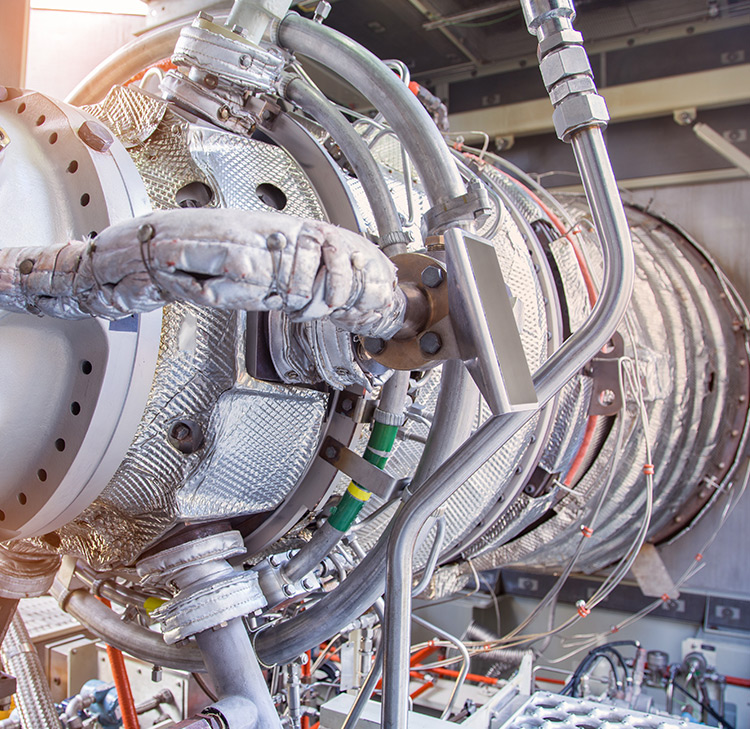

This EuroMaTech Principles, Applications and Performance of Pumps, Compressors and Turbines training course will focus on the importance of rotating machinery such as pumps, compressors and turbines of various designs and applications, which are encountered throughout process industry, petrochemical and oil and gas industries. This EuroMaTech training course will start with an introduction to liquid and gas systems including pressure and head, capacity and flow, friction head losses & operational dynamics. Centrifugal and positive-displacement pumps, compressors and turbines, will all be introduced, together with their main construction and parts.The application of the different types of pumps, compressors and turbines will be discussed along with their suitability for different operational duties. Operation, troubleshooting and maintenance will also be dealt with.

The key highlights of this EuroMaTech training course are:

- Solid knowledge of basic principles of fluid flow

- Optimisation of the operation and maintenance of different types of pumps, compressors and turbines

- Confidence to troubleshoot problems related to pumps compressors and turbines, thereby avoiding repetitive failures

- Allow tighter control of maintenance budgets by the avoidance of unplanned equipment failures in service

TRAINING OBJECTIVES

- Have an understanding of relevant fluid laws and the different types of pumps and their associated terminology

- Have an understanding of Centrifugal and positive displacement pumps and compressors, and their related components

- Know how to calculate and use pump performance curves and pumping system requirements and have an understanding of different parameters affecting thier operation.

- Be able to operate pumps and compressors as close as possible to the design efficiency

- Know the different types and major components of turbines

- Understand the working principles and characteristics of turbines and know the major components

- Have the ability to perform troubleshooting of systems involving pumps, compressors and turbines

- Have learnt about selection, operation and maintenance strategies

WHO SHOULD ATTEND?

- Technicians and Operators

- Graduate Engineers

- Mechanical and Process Engineers

- Plant Engineers responsible for operations, maintenance and troubleshooting

- Maintenance and Instrumentation Professionals

- Technologists and Facility Operators

- Supervisors, Team and Project Leaders

This EuroMaTech Principles, Applications and Performance of Pumps, Compressors and Turbines training course will also of benefit anyone who wishes to update themselves on pump, compressor and turbine technology, judge the suitability of different types of pumps, compressors and turbines for their needs, and learn how to operate and maintain them for the benefit of their organisations.

TRAINING METHODOLOGY

This EuroMaTech Principles, Applications and Performance of Pumps, Compressors and Turbines training course will be conducted along workshop principles with formal lectures, computer simulation, relevant videos, case studies and interactive worked examples. Relevant case studies will be provided to illustrate the application of each tool in an operations environment. Each learning point will be re-enforced with practical exercises. There will be ample opportunities for discussion and sharing experiences. Hard and soft copies of the programme manual will be presented to each delegate.

TRAINING SUMMARY

The knowledge gained in this EuroMaTech training course will provide better understanding of pumps, compressors and turbines in complex operating conditions. The delegates will be able to develop a proactive maintenance system which will allow better inspection, control and monitoring with the goal of avoiding unplanned equipment failures and maximising compressor and turbine availability and reliability.

This EuroMaTech training course will give the delegate the required level of technical knowledge and skill to achieve that personal satisfaction.

- Understanding of reciprocating and rotating equipment operating and maintenance techniques

- Ability to put in place measures to quantify equipment condition

- Interface with pump, compressor and turbine equipment providers

- Identify and specify new and replacement pumps, compressors and turbines

- Ability to operate and troubleshoot rotating equipment

TRAINING OUTLINE

Day 1 : Introduction and Fluid Laws

- Introduction to basic types and principles of, Pumps, Compressors and Turbines

- Basic liquid and gas Laws

- Understanding Head

- Types of flow and losses

- Net Positive Suction Head (NPSH)

Day 2 : Pumping Systems, Pump Performance and Pump Type Construction

- Pump type and Performance (Centrifugal and Positive Displacement)

- Pump characteristics. Head, Capacity, Power, Efficiency and Net Positive Suction Head (NPSH)

- Pump Curves and System Curves.

- Positive Displacement Pumps, Reciprocating and Rotary

- Dynamic Pumps Types, Centrifugal, Axial, Mixed, Multistage, etc.

- Sealing Systems. Conventional Packing Glands and Mechanical Seals

Day 3 : Compressor Construction, Types, Characteristics and Performance

- Positive displacement compressors, reciprocating compressors, reciprocating compressors, diaphragm compressors.

- Rotary compressors, rotary screw compressor, lobe type air compressor, sliding vane compressors, liquid ring compressors

- Dynamic compressors, centrifugal compressors, axial compressors

- Principle of operation and performance curves

- Surging and choking problems

Day 4 : Turbine Types, Construction and Performance

- Turbine Types

- Gas Turbines

- Steam turbines

- Turbine Operation

- Main components

- Nozzles

- Stator and Rotor Blades (Vanes) Configuration and Flow

- Aerofoil and Twisted Contours

- working cycle of a gas turbine, representation of the Pressure-Volume diagram (indicator card)

- Stages

Day 5 : Troubleshooting & Maintenance

- Potential Failure Analysis

- Troubleshooting

- Review of common faults

- Developing a Preventive Maintenance Plan

- Vibration causes, forcing frequency causes, unbalance, misalignment, mechanical looseness, bearing defects, gear defects, oil whirl, blade or vane problems

- Cavitation

- Water Hammer

- What causes water hammer?

- Solutions for water hammer

- Review of the Week & Wrap-Up

CALL ME BACK

Do you wish for us to conduct this course at your premises?

Discover In-House Solutions

ACCREDITATION

EuroMaTech is registered with the National Association of State Boards of Accountancy (NASBA) as a sponsor of continuing professional education on the National Registry of CPE Sponsors. State boards of accountancy have final authority on the acceptance of individual courses for CPE credit.

Euromatech is a Knowledge & Human Development Authority (KHDA) approved training institute in Dubai, licensed and approved to deliver training courses in the UAE.

The KHDA is the regulatory authority in the UAE, that oversees administering, approving, supervising, and controlling the activities of various education providers in the UAE. We are proud of our commitment to ensuring quality training courses and status as a KHDA-approved training provider.

Taught by our team of highly qualified trainers, our KHDA approved training courses will provide you with an enriching learning experience and practical knowledge that will help you future-proof your career and support professional development within your organisation.