An Intensive 5-day Training Course

Layers of Protection Analysis (LOPA)

- Format: Classroom

- Duration: 5 days

- Language: English

- Accredited: CPE, KHDA Certified training courses

CLASSROOM DATES

INTRODUCTION

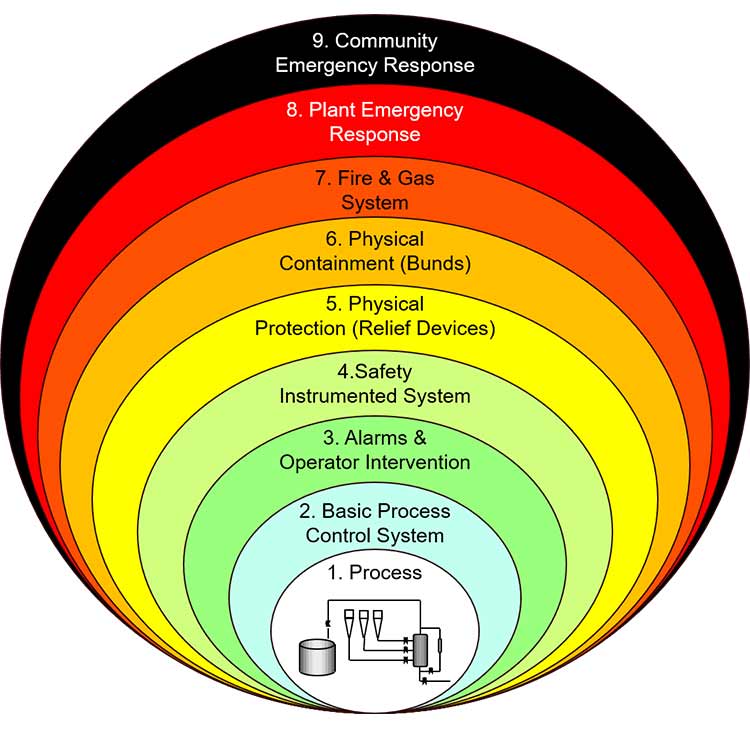

This highly participative Layers of Protection Analysis training course combines both qualitative and quantitative elements of hazard evaluation and risk assessment to analyze and judge the adequacy of existing or proposed safeguards against process deviations and accident scenarios. It uses an order of magnitude approach to quantify the likelihood of causes, likelihood of failure of Independent Protection Layers (IPLs), and estimate the consequences for chosen accident scenarios. These approximations are used to estimate the risk of a scenario.

A key to the success of Layers of Protection Analysis (LOPA) is its rules for judging if protection layers are truly independent. Because of these rules, LOPA helps the analysts make consistent judgments of if the risk of a scenario is “as low as reasonably practical (ALARP)”. The training course contents are based and taught on the guidelines from the AIChE / HSE. The training course covers all aspects of how to apply this very useful technique not only in the selection and analysis of Safety Integrated Systems but also for other applications within an organization such as Capital Improvement Planning, Management of Change, Risk Based maintenance programs, Incident Investigations etc.

TRAINING OBJECTIVES

- When and how to use LOPA

- How to identify which scenarios from a HAZOP or other qualitative analysis could benefit from LOPA

- How to systematically create risk scenarios for new processes or for existing processes under change

- How to establish risk acceptance (risk tolerance) criteria for use within your company (this is also called development of ALARP criteria) and how to depict this in a Risk Matrix or in a formula

- How to calculate “as-is” risk for a cause-consequence pair:

- How to estimate the frequency of the initiating event

- How to determine the consequence for the scenario (unmitigated)

- Understand what is meant by “independence” and “uniqueness” with respect to the safeguard layers (IPLs)

- How to calculate the value of each IPL

- How to determine the risk of a LOPA scenario and how to determine how much further risk reduction (if any) is necessary

- How to use LOPA to determine the Safety Integrity Level (SIL) necessary for an instrument IPL (to comply with the requirements of IEC 61508/61511 for safety instrumented systems)

- How to document LOPA

- How other companies worldwide use LOPA to:

- Decide which PHA / HAZOP recommendations to reject and which to accept

- Focus limited resources within mechanical integrity departments and operations on what is critical to manage risk to ALARP

- Avoid wasting resources on the added cost and unproductive sophistication that often occurs when they instead quantify risk using QRA methods such as fault tree and event tree analysis

WHO SHOULD ATTEND?

- Professionals and leaders who wish to learn more about strategies for improving Process Safety Management and the use of the various Layers of Protection to improve the Safety Integrated Systems and Process Safety of their operations

- Professionals and leaders within an organization responsible for Capital Improvement Planning, Management of Change, Risk Based maintenance programs, Incident Investigations, Emergency planning and response, Facility siting and or design

- Personnel moving into roles that are participating or are responsible for the Safety Integrated Systems and Process Safety of their operations or Capital Improvement Planning, Management of Change, Risk Based maintenance programs, Incident Investigations, Emergency planning and response, Facility siting and or design

TRAINING METHODOLOGY

The EuroMaTech training course will combine presentations with interactive practical exercises, supported by video materials, activities and case studies. Delegates will be encouraged to participate actively in relating the principles of Layers of Protection Analysis to the particular needs of their workplace.

TRAINING SUMMARY

This Layers of Protection Analysis training course covers essential skills such as understanding the principles of Process Safety Management, the developing and analysis of Layers of Protection, determine the safety integrity levels required and developing and implementing Safety Integrated Systems.

TRAINING OUTLINE

Day 1 : Introduction to Layers of Protection Analysis (LOPA)

- Learning objectives and goals of using the LOPA technique

- What is LOPA? How is LOPA applied?

- Terminology and definitions

- Where does LOPA fit into Process Safety and the other Process hazard Assessment methods?

- How to Implement LOPA

- Introduction to Reliability Technology

- Reliability of components, series and parallel systems

- Types of maintenance and inspection regimes

Day 2 : Identification of Initiating Events

- Hazard & Operability ‘HAZOP’ Study

- HAZOP Workshop

- Risk Assessment & Risk Management

- Analysis of Major Accidents in relation to LOPA:

- Piper Alpha

- BP Texas Refinery Explosion

- Bhopal

- Buncfield

Day 3 : Estimating the Consequences and Severity

- Estimating the Consequences and Severity

- Mechanics of Fire, Explosion and Toxic Releases

- Consequence evaluation approaches for LOPA

- Developing Scenarios

- Selecting candidate scenarios from qualitative (brainstorming) hazard evaluations

- Scenarios from design questions and from incidents

- Deciding on the right cause-consequence pair to define each scenario

- Identifying Independent Protection Layers

- Purpose

- Definition and Purpose of an IPL

- IPL Rules

- LOPA IPL Assessment

- Examples of IPL’s

- Preventive IPL vs Mitigating IPL

- Continuing Examples

- Protective Systems Design and Reliability

- The concept of Fractional Dead Time ‘FDT’

- High Integrity Protective Systems

- Selection of Safety Integrity Levels ‘SIL’

- Using LOPA to make risk decisions

- Comparing Calculated risk to Scenario Risk Tolerance

- Expert Judgement

- Using Cost / Benefit Comparisons

- Comparison of risk decision approaches

- Cumulative Risk Criteria vs. Scenario Criteria

- Continuing Examples

Day 4 : Implementing LOPA

- Is the company ready for LOPA?

- What is the current foundation for risk assessment

- What data is required?

- Will IPL’s remain in place?

- How are risk tolerance criteria established?

- When is LOPA used?

- The Bow-Tie Model

- Discussion: Typical implementation tasks and implementation barriers

Day 5 : Using LOPA for other applications

- Mechanical Integrity Programs / Risk based inspection / Risk based Maintenance Programs

- Risk based Operator Training

- Emergency Response Planning

- Credible design basis for Overpressure Protection

- Evaluating Facility Siting Risks

- Evaluate the need for Emergency Isolation Valves

- Evaluate taking a safety system out of service

- Incident Investigations

- Incidents and Failure Root-causes

- Programme Evaluation and General Discussion

CALL ME BACK

Do you wish for us to conduct this course at your premises?

Discover In-House Solutions

ACCREDITATION

EuroMaTech is registered with the National Association of State Boards of Accountancy (NASBA) as a sponsor of continuing professional education on the National Registry of CPE Sponsors. State boards of accountancy have final authority on the acceptance of individual courses for CPE credit.

Euromatech is a Knowledge & Human Development Authority (KHDA) approved training institute in Dubai, licensed and approved to deliver training courses in the UAE.

The KHDA is the regulatory authority in the UAE, that oversees administering, approving, supervising, and controlling the activities of various education providers in the UAE. We are proud of our commitment to ensuring quality training courses and status as a KHDA-approved training provider.

Taught by our team of highly qualified trainers, our KHDA approved training courses will provide you with an enriching learning experience and practical knowledge that will help you future-proof your career and support professional development within your organisation.