An Intensive 5-day Training Course

Fitness for Service Assessment of Pressure Vessels, Tanks and Piping Systems Using API 579-1 and ASME FFS Standards

- Format: Classroom

- Duration: 5 days

- Language: English

- Accredited: CPE, KHDA Certified training courses

CLASSROOM DATES

INTRODUCTION

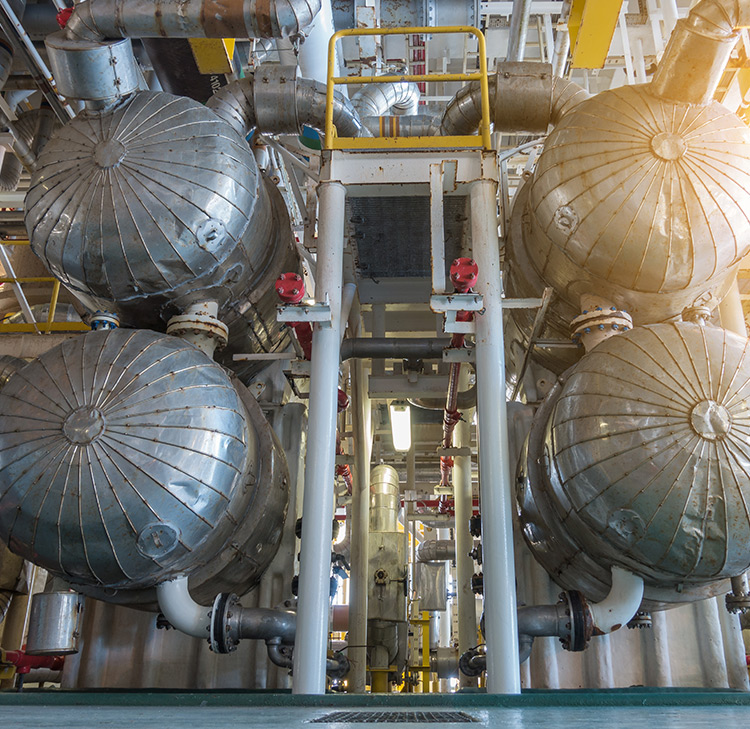

Pressure Vessels, Tanks and Piping Systems are very important equipment for oil, gas and petrochemical industry. This EuroMaTech training course will enable delegates to learn how to apply API 579-1 / ASME FFS-1 codes “Fitness-for-Service” to evaluate the integrity and quantify the remaining life of stationary equipment including pressure vessels, storage tanks, piping systems. Proper implementation of those codes ensures minimum down time and maintenance costs through cost effective run-repair-replace decisions and select the appropriate repair options.

Key highlights of this EuroMaTech training course are:

- Understanding design, operation and maintenance strategies for stationary equipment

- Identification of failure modes and material degradation mechanisms: stress corrosion, cracks, blisters, in the framework of API 579 / ASME FFS

- Methodology for quantitative evaluation of remaining life of the equipment based on its fitness for service

- Integrity of stationary equipment based on material properties of strength and toughness

- Application of fitness-for-service methodology for optimization of maintenance and repairs

TRAINING OBJECTIVES

- Understand factor of safety and P-F graphs for pressure vessels, tanks and pipelines

- Outline the latest techniques of assessing the fitness-for-service of pressure vessels, tanks and piping systems, advantages and limitations

- Acquire a methodology for quantitative evaluation of the remaining life of equipment

- Choose and implement cost-effective run-repair-replace decisions based on API 579 / ASME codes

- Learn how to assess defects in pressure vessels, storage tanks and piping systems

WHO SHOULD ATTEND?

- Pipelines, tanks and pressure vessels operation and maintenance professionals

- Integrity management and reliability engineers

- Corrosion and materials engineers

- Plant and project engineers

- Inspection engineers for pressure equipment and piping systems

TRAINING METHODOLOGY

This Best Practices on Damage and Integrity Management (API 579-1 / ASME FFS-1) training course will be conducted along workshop principles with formal lectures, and interactive worked examples. The emphasis in the course will be on explanation of all technical phenomena and providing answers to problems that are encountered in everyday industrial practice. Each learning point will be reinforced with practical examples. There will be a plenty of opportunities for active discussions and sharing experiences.

TRAINING SUMMARY

This EuroMaTech training course will provide practical knowledge and experience in evaluating the integrity and overall fitness for service of stationary equipment. It will provide a method of determining the remaining life of pressure vessels, storage tanks, piping systems and pipelines. The training course will also cover basic principles of application of API579 -ASME Code rules related to material properties that are important for consideration of stresses and fractures when making important decision about equipment regarding options: run or repair or replace.

TRAINING OUTLINE

Day 1: Equipment Classifications, Failures and Assessment Methods

- Classification of equipment used in process plants

- Why and how equipment fail

- The concept of Fitness For Service

- Fitness for Services API & ASME codes

Day 2: Design Parameters Calculations and Testing Methods

- Calculation of minimum allowable thickness (MAT)

- Determination of maximum allowable working pressures (MAWP)

- Damage mechanisms, deterioration and failure modes

- Non-destructive testing and evaluation (NDTE) methods

Day 3: Corrosion and Erosion Mechanisms and Protection Strategies

- Assessment of general metal loss: corrosion mechanisms

- Assessment of local metal loss: typical mechanisms

- Assessment of pitting corrosion and blisters

- Metal loss and corrosion protection strategies

Day 4: Welding Methods, Cracks and Creep

- Welding methods: advantages and limitations

- Weld misalignment and shell distortions

- Assessment of components operating in the creep range

- Assessment of Crack-Like Flaws

Day 5: Other Related Damage Mechanisms – Fire and Mechanical Damage

- Assessment of fire damage

- Assessment of dents, gouges, and dent-gouge combinations

- Assessment of laminations

CALL ME BACK

Do you wish for us to conduct this course at your premises?

Discover In-House Solutions

ACCREDITATION

EuroMaTech is registered with the National Association of State Boards of Accountancy (NASBA) as a sponsor of continuing professional education on the National Registry of CPE Sponsors. State boards of accountancy have final authority on the acceptance of individual courses for CPE credit.

Euromatech is a Knowledge & Human Development Authority (KHDA) approved training institute in Dubai, licensed and approved to deliver training courses in the UAE.

The KHDA is the regulatory authority in the UAE, that oversees administering, approving, supervising, and controlling the activities of various education providers in the UAE. We are proud of our commitment to ensuring quality training courses and status as a KHDA-approved training provider.

Taught by our team of highly qualified trainers, our KHDA approved training courses will provide you with an enriching learning experience and practical knowledge that will help you future-proof your career and support professional development within your organisation.